According to scientists at the Vytautas Magnus University Academy of Agriculture (VMU MAA), one of the most commonly used technologies in modern intensive agriculture involves spraying fields with pesticides and liquid mineral fertilisers. This chemical application, often referred to as “chemical rain,” can be carried by the wind for distances up to 30 meters to nearby homesteads, apiaries, water bodies, and organic farms. In response to this concern, VMU ŽŪA experts are collaborating with the business company UAB Nando and international partners to conduct experiments in a wind tunnel at the laboratory. Their goal is to develop a solution that could be potentially commercialized in the future, aimed at reducing the risk of these sprayed chemicals reaching the surrounding environment in close proximity to the treated field.

Dainius Steponavičius, the head of the team and a professor at the Faculty of Agricultural Engineering at VMU MAA, expressed his satisfaction with the team’s achievement in securing the opportunity to conduct new research and experiments, as well as to present proposals to businesses. The project, undertaken in collaboration with UAB Nando and their foreign partner, the Romanian University of Krajova, has received funding from EUREKA. Specifically, the project will be financed under the MITA measure “Promoting the commercialization and internationalization of R&D results.”

D. Steponavičius foresees that spraying technology in agriculture will remain in use for the foreseeable future, not only in Lithuania but also globally. Therefore, the crucial mission for scientists is to develop solutions that enhance the environmental friendliness of the spraying process. By focusing on creating environmentally sustainable approaches, they aim to ensure that this essential agricultural practice aligns with ecological considerations and minimizes its impact on the environment.

“Sprayers applying herbicides, fungicides, insecticides, liquid mineral fertilisers, and plant growth regulators are commonly used multiple times throughout a season in the same field. The modern self-propelled sprayers feature a boom with mounted nozzles, which can have a width of 30 meters or more. During spraying, the boom extends about half a meter above the plants. However, crosswinds or frequent gusty winds can cause the dispersion of poisonous droplets over long distances, reaching up to 30 meters away. This phenomenon of droplet drift poses significant environmental and economic challenges,” he explains.

To address this issue, various technical measures are being explored, including optimizing the sprayer’s speed, using different nozzle types (e.g., injector nozzles), adjusting the pressure of the spraying liquid, installing beam dampers, and employing other techniques to shield droplets from the wind.

An alternative approach involves adding an anti-drift agent to the spray tank, modifying the properties of the droplets, such as size and surface tension. The USA has been at the forefront of recent developments in such agents.

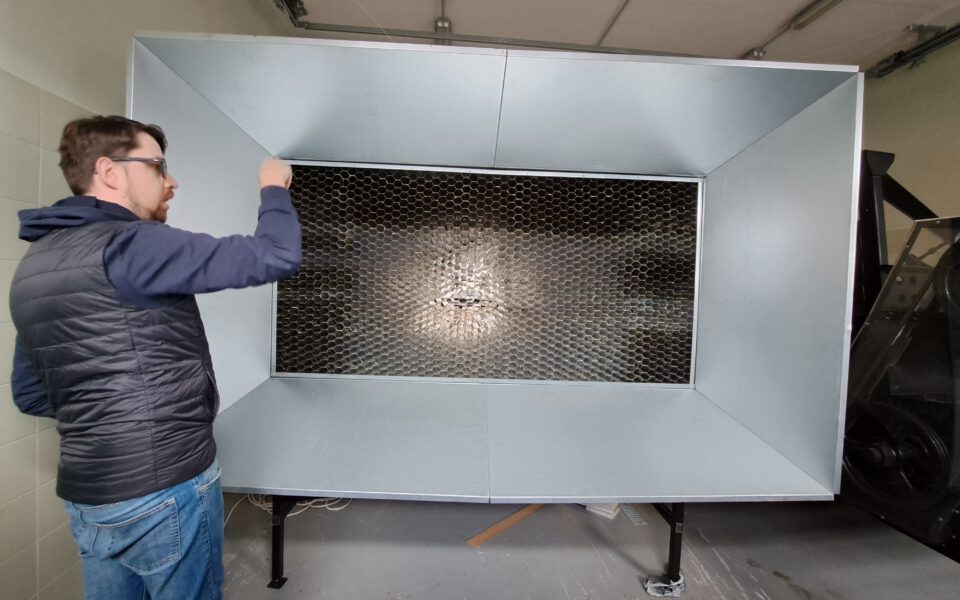

Initial drift tests of droplets affected by the product have commenced in the wind tunnel at the Agricultural Machinery Technological Processes Laboratory of VMU ŽŪA. Subsequent experiments will be conducted in real field conditions.

In a collaborative effort between scientists and entrepreneurs, UAB Nando is responsible for developing the original Lithuanian preparation, while VMU ŽŪA is tasked with testing its effectiveness and comparing it with similar products from other countries. The Romanian University of Krajova will explore the feasibility of using the preparation in Romanian conditions and its potential demand in the Romanian market.

The pursuit of innovative solutions to mitigate unwanted downwind drift of sprayed plant protection products is driven by increasing environmental regulations and the European Green Deal. The objective is to reduce environmental pollution and climate impacts, safeguard human life, animals, and plants, and support companies in becoming global leaders in clean products and technologies.

The project aims to develop a new formulation based on mixtures of natural oils and ethoxylated alcohols within a two-year timeframe, subjecting it to rigorous scientific studies to assess its effectiveness in reducing the undesired downwind drift of sprayed pesticide droplets.

Upon successful completion of the development and testing phases, the new formulation is slated to undergo evaluation and registration as a loss-reducing spray adjuvant at the esteemed Julius Kühn Institute in Germany.